Current:Home > News information >

Exposure time and band of UVLED linear light source

source:未知 date: 2019-03-26 10:56 hits:

1. In order to reduce the cost of consumables, the usage time of the UVled line light source can generally reach 25,000-30,000 hours, while the traditional LAMP irradiator needs to replace the lamp tube about 2000 hours. The LED-UV uses cable output and no optical fiber light guide. The LED can reduce the cost of consumables, improve the utilization rate of equipment and bring more user experience for you.

2. Lock the interface parameters to prevent bad press, direct COM, convenient peripheral communication, foot control, manual automation, easy control.

3. Thermal radiation is small, the irradiator uses the light-emitting component of the UV-LED electric power, the spectral wavelength is 365 nm, the UVled line light source does not emit infrared light, so there is no temperature rise on the surface of the irradiated product, the countdown of irradiation power time is displayed digitally, which is intuitive and convenient to understand the irradiation process.

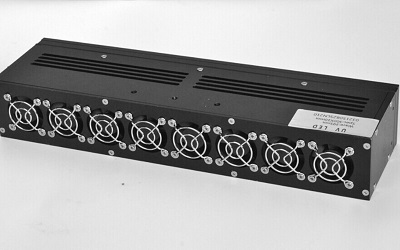

4. Ultraviolet ray source emits high-energy and high-purity ultraviolet light, uses new high-energy ultraviolet LED, quickly completes the curing of ultraviolet glue, greatly improves the production efficiency and unique fan heat dissipation, quickly discharges the heat of the chip, improves the stability of power output, and prolongs the life of the LED.

5. Energy-saving and environmental protection, low power consumption of LED, no need of lamp preheating, instantaneous high power up to 100%, that is, on-demand, high efficiency of ultraviolet photoelectric conversion, and does not contain toxic mercury, and will not produce ozone. It is a safe and environmentally friendly alternative to traditional light sources.

6. In the course of irradiation, it is easy to inquire the process of channel UV irradiation, search automatically, and give alarm for errors.

7. Equipment can be used in different processes. According to actual needs, users can choose and match external extension cables.

8. Small volume design, the volume of LED controller is about 1/8 of the volume of the traditional LAMP irradiator, which makes the installation of the equipment simpler. The design of the small irradiator of the UVLED line light source fully considers the space requirements of precision production, so that the installation of the equipment is more convenient, fixed power, step power, perfectly embodying the universal design, liquid crystal display, and intuitive operation.

Characteristics of UVLED illuminator

1. The LED linear light source is a cold light source, without thermal radiation, and the temperature of the irradiated product remains unchanged.

2. Without preheating and instantaneous lighting, the ultraviolet power output can reach 100% immediately, and the irradiation intensity can reach 8000mW/cm2.

3. The machine adopts a miniature fuselage, and the irradiation head is drawn from the back of the fuselage. It makes it easy to integrate the equipment into the fully automatic production line and equipment.

4. It is a safe and environmentally friendly alternative to the traditional light source that does not use toxic mercury or produce ozone.

5. Cost reduction, direct LED irradiation, no need to output optical cables, reduce the loss of optical cables.

Futansi (Shanghai) Electronic Technology Co., Ltd. specializes in the production of UV LED point light source, UV LED line light source, UV LED surface light source, UV LED curing furnace, UV LED light curing machine, UV LED glue curing machine, UV LED light source curing equipment, UV energy meter, UV illuminometer.

National unified service hotline

National unified service hotline