Current:Home > News information >

Technology Advantage and Application of Uvled Curing Light S

source:未知 date: 2019-04-08 14:01 hits:

UV LED curing light source can improve production efficiency

Because of the short curing time and no need of heat source and solvent, the linear speed of 400 m/min can be achieved by UV process, so the production efficiency can be greatly improved. After printing with UV ink, UV polishing machine can obtain high gloss and uniform surface. After polishing, packaging processes such as die cutting, indentation, gluing and stamping can be completed immediately, which is very conducive to the development of high-speed printing.

UV LED curing light source can improve product performance

UV printing is suitable for a wide range of printing materials. The actual UV printing has clear dots, good tone reproduction, bright ink and high consistency. At the same time, because the UV curing process is a photochemical reaction process, both the ink layer and the light oil layer have the advantages of strong adhesion, durability, water resistance, chemical corrosion resistance, wear resistance and aging resistance.

UVLED Curing Light Source Can Improve Economic Benefit

High production efficiency and high output mean high economic benefits. At the same time, high speed also means reducing the storage cost and capital pressure of raw materials and finished products. At the same time, because the energy consumption of UV curing is very low, this makes the operation cost of ordinary times also reduced to a great extent.

UVLED solidified light source can meet environmental protection standards

The whole curing system of UV printing is solvent-free system, that is, 100% solvent-free formulation, and VOC-free, which just meets the requirements of today's environmental protection. This is another important feature of UV curing ink. Because the solid content of UV curing ink is close to 100%, VOC (organic volatiles) is hardly contained, that is, volatile organic compounds are not emitted or rarely emitted during curing process, which will not cause more harmful environmental pollution, and less waste, save energy, and do not have to worry about dealing with harmful flammable and explosive materials. It is an environmentally friendly ink.

Application examples of UV-LED curing light source:

1 Hard disk head assembly (encapsulation of read and write head, gold wire fixation, bearing, coil, chip bonding, etc.)

Motor and component assembly (wire, coil fixed, coil end fixed, PTC/NTC component bonded to protect transformer core)

3 DVD/Digital Camera (Lens, Lens Paste, PCB Reinforcement)

4 Sensor Production (Gas Sensor, Photoelectric Sensor, Optical Fiber Sensor, Photoelectric Encoder, etc.)

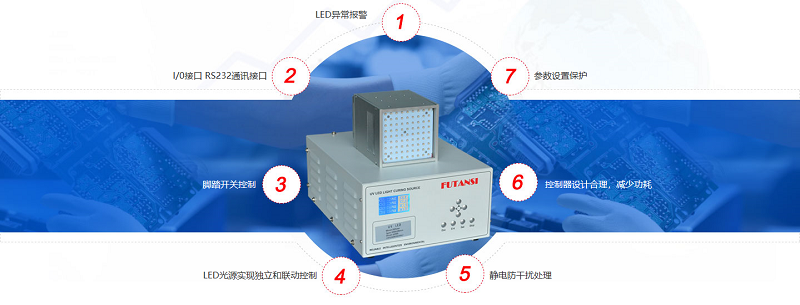

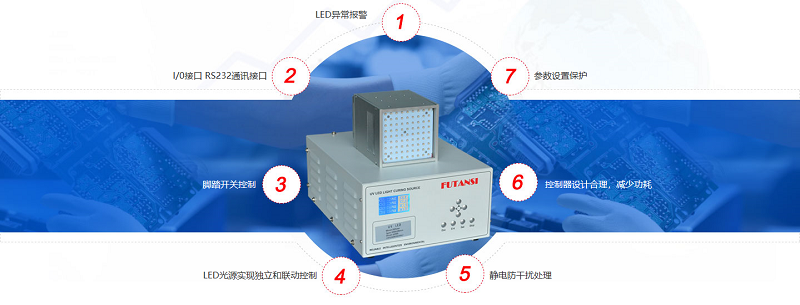

Futansi (Shanghai) Industrial Equipment Co., Ltd. mainly produces UV LED point, line and surface light source, UV LED curing lamp, UV LED oven, and UV LED equipment.

National unified service hotline

National unified service hotline