Current:Home > News information >

Is a small UV LED light source comparable to a traditional m

source:未知 date: 2019-04-28 14:58 hits:

Many customers feel very strange, said a small light source irradiation head, put some beads inside, a few hundred watts, less than kilowatts of light source irradiation head can replace a few kilowatts, the luminous area of such a large lamp?

In fact, the secret inside is still very simple and easy to understand. The irradiation head of UV LED uses high-power UV LED beads as light source and controls various control modes through controllers to convert electrical signals into light signals. That is, high-power UV LED chips produce 365/385/395/405+5nm ultraviolet radiation with high energy and high purity. Ultraviolet light forms point light source and UV LED line through a special focusing lens system. Light source, UV LED surface light source and other sizes of light-emitting shape, so that its energy is highly focused on the UV glue UV ink, according to its process requirements, rapid curing, and compared with the lamp, the following advantages and made a comparison:

Extra long service life

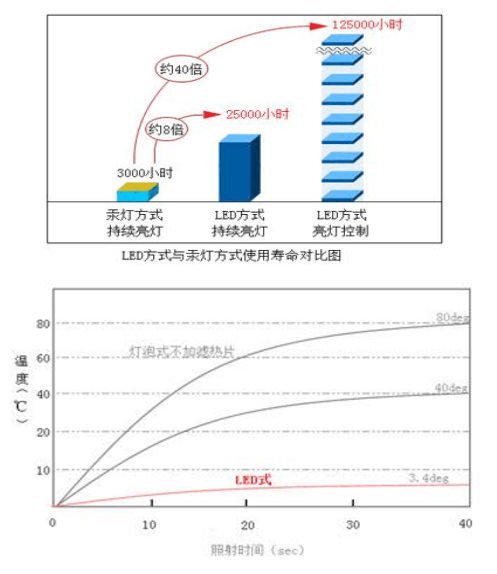

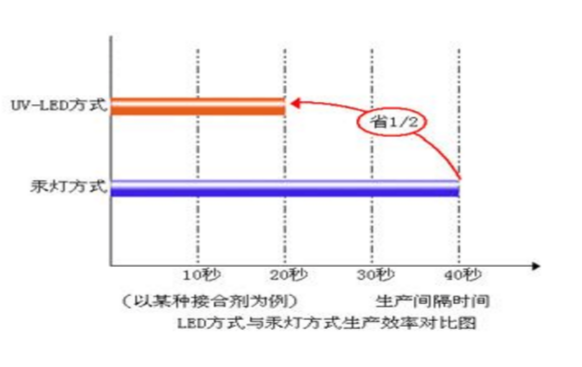

Compared with traditional mercury lamp curing equipment, the service life of mercury lamp is only 1000-3000 hours, while that of UVLED curing device reaches 20000-30000 hours. LED can be lighted instantly when ultraviolet light is needed. When DUIY = 1/5 (preparation time = 5 irradiation time = 1), the service life of LED is 40 times longer than that of mercury lamp, which reduces the time of replacing lamp tube, improves production efficiency and saves energy. When traditional mercury lamp curing equipment works, because mercury lamp needs preheating, opening and closing will affect the life of mercury lamp, so the lamp tube must always be lit, not only shorten the life of mercury lamp, but also cause unnecessary power consumption.

Ultra-high irradiation intensity:

Ultraviolet light is irradiated with high precision and high intensity by using high power UV LED chip and special concentrating lens. By using new optical technology and manufacturing technology, the illumination intensity of mercury lamp is twice as high as that of traditional mercury lamp illumination mode, which makes UV glue or UV ink cured faster, shortens production time and greatly improves production efficiency. The output energy of traditional mercury lamp curing equipment decreases with the increase of the number of branches, while the irradiation head of UVLED mode emits light independently, and the irradiation intensity is unaffected by the increase of channels, and keeps a large value.

Thermal radiation:

Using high-power UV-LED chip, it emits 365/385/395/405+5 nm pure ultraviolet light, without infrared light and other miscellaneous wavelengths, and the surface temperature of the irradiated product rises below 5 degrees Celsius; while the traditional mercury lamp curing equipment will make the surface temperature of the product rise to 40-80 degrees Celsius, which will easily displace the positioning of the product and cause adverse product, so the curing method of UV-LED line/surface light source is most suitable for thermal sensitivity. High-precision bonding process requirements for substrate, lens bonding and electronic products, optical fibers, etc.

Futansi(Shanghai) Electronic Technology Co., Ltd. produces UV LED, UV LED light source, UV LED light source, UV LED curing machine, UV LED curing lamp, UV LED irradiator, UV LED point light source, UV LED line light source, UV LED surface light source, UV LED oven, UV LED curing furnace UV curing lamp, UV glue dryer.

National unified service hotline

National unified service hotline