Current:Home > News information >

UV LED Curing Machine for Optical Fiber Coating

source:未知 date: 2019-08-20 08:20 hits:

Optical fibers are composed of core, cladding and coating. The typical core is pure silica glass or germanium-doped silica glass, while the cladding may be pure silica glass or fluorine-doped silica glass. The diameter of the core depends on the application of the optical fiber, and the diameter of the cladding is generally 125 um. The thickness of polymer coatings for optical fibers (generally epoxy acrylate or polyacrylate) is about 60 microns. Therefore, the diameter of the optical fiber is 245 um. Among them, the inner coating is soft (low modulus of elasticity, only a few hundred MPa), while the outer coating is hard (high modulus of elasticity, up to tens of thousands MPa). The inner coating is used to protect the surface of bare optical fibers from mechanical damage and to buffer the external stress in the use of optical fibers. Harder outer coating is beneficial to wear resistance of optical fibers. When optical fibers are fused and connected, the coating must be cleanly removed from the surface of glass fibers. In order to provide a coating that can be removed with very little force without leaving any residue, it is necessary to understand the coating properties that affect peelability. To understand these effects, it is necessary to distinguish the peeling force from the pulling force of the coating. The peeling force of the coating is determined by the external coating of the optical fiber, and the pulling force of the coating, that is, the bonding force between the inner coating of the optical fiber and the quartz glass coating, depends on the inner coating of the optical fiber. In actual production, the curing of the outer coating basically reaches the saturation state, so it is necessary to control the UV curing dose reaching the inner coating of the optical fiber to ensure that the pull-out force of the coating meets the requirements of the optical fiber specification.

Influencing factors of ultraviolet curing of optical fiber coatings:

In actual production, there are many factors affecting the curing of optical fibers, which are complex. There are several methods to measure the curing degree of ultraviolet curable acrylate coatings and the pull-out force of the coatings on optical fibers. Some factors affecting the curing of optical fibers and the corresponding new energy of optical fibers are discussed.

1. The influence of coatings. Ultraviolet curing coatings are generally composed of high-viscosity prepolymer, low-viscosity monomer, photoinitiator and other fillers. They are thixotropic fluids whose viscosity varies with temperature.

2. The influence of ultraviolet curing equipment: Ultraviolet curing equipment has its service life, and its illumination intensity will be weakened with the prolongation of service time, thus affecting the curing degree and curing quality of optical fibers, and affecting the peeling force of coatings and other optical fibers. Traditional UV lamp is very obvious in this respect, but as far as UV LED curing equipment is concerned, the lifetime and illumination intensity of UV point light source have been greatly improved. There is no need to worry about these reasons when using UV LED as a light source.

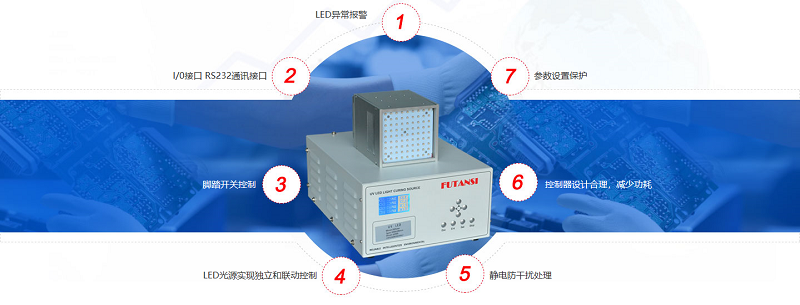

Futancy produces UV curing lamp, UV glue dryer, UV LED point light source, UV LED line light source, UV LED surface light source, UV LED oven, UV LED curing oven, UV LED tunnel oven and UV oven.

Futancy produces UV curing lamp, UV glue dryer, UV LED point light source, UV LED line light source, UV LED surface light source, UV LED oven, UV LED curing oven, UV LED tunnel oven and UV oven.

National unified service hotline

National unified service hotline